Products

※Please watch videos.

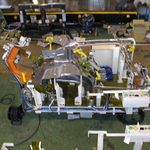

HEMMING APPARATUS

(1) Hemming apparatus

It is suitable for small production volume by the robot roller system.

It can flexibly corresponds to the small capital investment and model change.

The equipment investment can be reduced to about 1/50 compared with a conventional large press machine for hemming.

The robot has a lower die for hemming, jigs to secure the outer and inner panels,and hemming rollers.

Two robots can be used simultaneously for greater output.

The robot is flexible, so hoods, left/right front/rear doors, and back doors can be hemmed simply by replacing the dies and jigs.

This robot is optimal for small-lot production and can flexibly handle remodeling.

(2)T/T (table top) Hemming

It is hemming system to operate the C-shaped frame with a blade by a hydraulic It is ideal for medium production volume.

Our tabletop (T/T) hemming machine is suitable for forming automobile cover parts in medium lots. This machine enables hemming in a very small space compared with conventional machines. A large press machine is generally used for hemming, but press hemming has disadvantages such as great equipment investment for the press machine and dies. Die replacement in lot production is also time-consuming. It is necessary to supply cover parts for 10 years after ceasing production and sufficient space must be secured to store the dies. The outer and inner panels are set on the lower die for tabletop hemming, and lifted hydraulically against a C-shaped frame with pre-bending and full bending blades for caulking. The equipment investment for tabletop hemming can be reduced to about a half that of press hemming, and the equipment area also becomes much smaller.

(3) Press Hemming

It is hemming system performed using a pressing machine. It is ideal for mass production.

We propose a press hemming method that is optimal for mass production, and exhibits cost effectiveness.

A cam mechanism is fully utilized to complete pre-hemming and full hemming with a single stomping, which can reduce pressing processing.

This reduces the initial investment on dies and also the product cost by streamlining the pressing process.

AUTOMOTIVE WELDING JIG APPARATUS

(1) Assembly jig

This device regulates part positions to enable precision welding of sheet metal parts for vehicle bodies.

This welding jig has achieved high quality by maximizing the use of 3D CAD, off-line teaching, and FEM analysis.

GENERAL INDUSTRIAL MACHINERY

(1) Circular cutter

Photo film manufacturing also generates film end materials, which are not acceptable as products. This machine cuts such film end materials into chips for recycling.

The film manufacturing process involves gradually winding a soft resin sheet while pulling it sideways so it becomes about 0.0001 mm thick. The parts where the film is clamped to pull it sideways and the non-standard parts at the beginning of the winding become waste. This circular cutter cuts the non-standard film parts into chips for recycling.

Our company possesses know-how regarding the shape of the film cutting blade and

how to secure blade clearance.

(2) High speed seater

This high-speed paper ejection device for offset-press printing is based on our many years of accumulated know-how.

This paper ejection system is flexible about varying paper thickness, and it runs fast.

The automatic adjustment mechanism reduces the maintenance load.

The paper stacking height after delivery is up to 1200 mm.

This contributes to improving productivity.

We meet various layout requests.

※Please watch videos.

<株式会社 柳田鉄工所>

群馬県太田市矢場町2707

TEL: 0276-45-4411

FAX: 0276-45-4405

mail:yanagita@tb3.so-net.ne.jp

営業時間 8:00 ~ 16:45(月〜金)

Yanagita Iron Works Co., Ltd.

2707 Yaba machi, Ota city,

Gunma prefecture,JAPAN